That sleek ceiling fan in your living room looks great, but what happens when you need to remove it for maintenance or replacement? Most homeowners panic when they realize there are no visible screws holding the canopy in place. Don’t worry—your screwless ceiling fan isn’t permanently attached. Modern manufacturers like Hampton Bay and others intentionally hide fasteners for aesthetic appeal, using clever mounting mechanisms that require specific removal techniques. This guide reveals exactly how to remove your ceiling fan without screws safely and efficiently, whether you’re replacing an outdated fixture or simply performing routine maintenance.

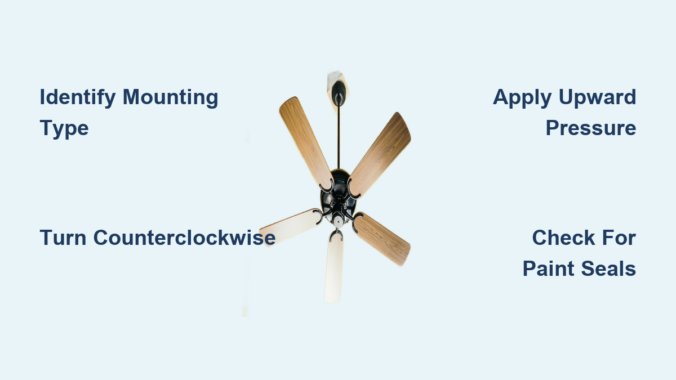

Understanding your specific mounting system is crucial before attempting removal. Most screwless fans employ either spring clip mounts or twist-lock mechanisms, each requiring a different approach. Rushing through this process without identifying your mechanism often leads to damaged components or unnecessary frustration. Taking just five minutes to examine your canopy properly saves hours of repair work later.

Identify Your Specific Mounting Mechanism

Before touching any tools, determine which hidden mounting system secures your canopy. This critical step prevents damage and wasted effort when you apply the wrong removal technique to your specific fan model.

Spring Clip Mount Characteristics

Run your fingers around the canopy perimeter to detect subtle resistance points where spring clips engage with the mounting bracket. These compression-based mechanisms create tension that locks the canopy securely without external fasteners. When you press upward near these points, you should feel slight give as the clips compress against the mounting ring interior. Hampton Bay and similar brands frequently use this design in their contemporary models.

Pro Tip: Shine a flashlight at a low angle across the canopy edge—this often reveals hairline seams where the spring clips engage with the mounting bracket. These visual markers guide your pressure application during removal.

Twist-Lock Design Identification

Look for directional arrows or alignment markers near the canopy’s edge that indicate proper rotation direction. Twist-lock mechanisms function like a bayonet mount, requiring counterclockwise rotation to disengage tabs from their slots. The canopy typically features a distinct upper ring that rotates independently from the base plate—this visible separation is your first clue about the mounting type.

Warning: Forcing rotation in the wrong direction can strip engagement tabs. If you see arrows pointing counterclockwise, rotate only in that direction with controlled pressure.

Critical Safety Steps Before Starting

Electrical safety must be your absolute priority throughout this entire process. Skipping proper precautions could lead to severe injury or even electrocution when handling electrical components.

Power Disconnection Protocol

Locate your circuit breaker panel and identify the correct breaker controlling your ceiling fan. Don’t rely on the wall switch—this only interrupts the control circuit, not the actual power supply. After switching off the breaker, verify power disconnection using a non-contact voltage tester on multiple points inside the canopy. Always test your voltage tester on a known live source first to confirm it’s working properly.

Time Estimate: This safety verification process takes 5-7 minutes but prevents potentially fatal accidents. Never skip this step, even if you’re experienced with electrical work.

Workspace Preparation Checklist

Position a sturdy ladder directly beneath the fan at a comfortable working height and secure it against wall movement. Place a drop cloth on the floor to catch falling debris and gather these essential tools before starting:

- Flat-head screwdriver or plastic putty knife

- Non-contact voltage tester

- Needle-nose pliers

- Work gloves

- Flashlight

Having everything within arm’s reach prevents dangerous ladder repositioning during the removal process.

Twist-Lock Canopy Removal Technique

For fans with twist-lock mechanisms (the most common screwless design), proper technique transforms what seems impossible into a simple quarter-turn operation.

Controlled Counterclockwise Rotation

Grasp the canopy firmly with both hands on opposite sides and apply steady downward pressure while initiating counterclockwise rotation. This downward force keeps the tabs engaged with their slots during rotation. Most twist-lock mechanisms require only a quarter to half turn—listen for audible clicks indicating clip release.

Troubleshooting Tip: If significant resistance occurs before any release, stop immediately. Resistance without progress often indicates a paint seal or debris accumulation, not a locked mechanism. Forcing rotation risks cracking the canopy housing.

Managing Uneven Release

When one side releases before others, support the partially detached canopy with one hand while working to disengage remaining tabs. Apply gentle pressure to the high side while encouraging release on the low side using a plastic putty knife. This uneven release is common with older installations where components have settled unevenly over time.

Pro Tip: Have an assistant support the canopy while you manage the release mechanism—this prevents sudden drops that could damage the fixture or injure you.

Spring Clip Release Methods

Spring clip mounts require different handling than twist-lock systems, focusing on compressing internal clips rather than rotation.

Targeted Pressure Application

Identify clip locations by feeling for subtle resistance points around the canopy perimeter. Apply firm, upward pressure directly at these points using your thumbs while supporting the canopy’s weight with your palms. Most spring clip systems require compressing 2-3 clips simultaneously to release the canopy evenly.

Visual Cue: Watch for slight separation between the canopy and ceiling as clips release—this gap should appear uniformly around the perimeter when done correctly.

Tool-Assisted Clip Release

For stubborn clips, insert a plastic putty knife into visible gaps at clip locations and apply gentle outward pressure. Work systematically around the canopy, releasing one clip at a time while maintaining support. Avoid metal tools that could scratch visible surfaces or damage plastic components.

Warning: Never use excessive force with prying tools—this often cracks the canopy rather than releasing clips. If resistance persists, reassess your mechanism type before continuing.

Handle Stubborn Canopies Without Damage

Even with proper technique, some canopies resist removal due to paint seals, dust accumulation, or component corrosion.

Paint Seal Breakthrough

Examine the canopy perimeter for visible paint lines indicating where previous painting created a bond between the canopy edge and ceiling. Carefully score along these lines using a utility knife blade held perpendicular to the surface. Make multiple shallow passes rather than one deep cut to avoid damaging the ceiling surface.

Time-Saver: Apply heat from a hair dryer to soften paint bonds before scoring—this reduces the force needed to break the seal.

Lubrication for Stuck Components

Apply penetrating oil along the seam between canopy and mounting bracket using a precision applicator tip. Allow 10-15 minutes for the lubricant to work into the mechanism before attempting removal again. Wipe away excess lubricant to prevent dripping onto surfaces below.

Alternative: For electrical safety, use silicone-based lubricants specifically designed for electrical components rather than petroleum-based products.

Wiring Disconnection Procedure

With the canopy partially lowered, safely disconnect the electrical components before complete removal.

Wire Identification and Documentation

Photograph the wiring configuration from multiple angles before disconnecting anything. Standard color coding applies: black (hot), white (neutral), and green/bare copper (ground). Modern fans may include additional wires for light kits or remote controls—note their connections carefully.

Critical Step: Support wires with one hand while disconnecting to prevent them from falling back into the ceiling cavity—a common mistake that adds 20+ minutes to the project.

Safe Wire Separation Technique

Grasp each wire nut firmly and rotate counterclockwise to disconnect. Separate house wiring from fan wiring and temporarily cap each set with wire nuts or electrical tape. Verify power remains off using your voltage tester on disconnected wires before proceeding.

Pro Tip: Tie a string to the end of house wires before lowering the canopy—this prevents them from disappearing into the ceiling and makes reconnection much easier.

Troubleshoot Common Removal Problems

Even with proper preparation, unexpected challenges may arise during screwless fan removal.

Canopy Rotation Failure

When twist-lock canopies refuse to rotate, check for these common issues:

– Paint seals bonding canopy to ceiling (solve by scoring perimeter)

– Dust accumulation in mechanism (solve with compressed air)

– Incorrect rotation direction (verify with visual markers)

Expert Note: If internal mechanism failure is suspected, consult manufacturer resources before forcing rotation—Hampton Bay and other major brands often provide model-specific service manuals online.

Uneven Canopy Release

Apply gentle downward pressure on the high side while working release tabs on the low side. Use a plastic tool to engage visible tabs near resistant areas while maintaining canopy support. Working with an assistant prevents sudden drops that could damage blades or motor housing.

Time Estimate: Resolving uneven release adds 5-10 minutes but prevents costly damage that would require professional repair.

Post-Removal Assessment and Next Steps

After successful removal, evaluate your fan’s condition to determine whether reinstallation or replacement is appropriate.

Component Inspection Checklist

Examine these critical areas before deciding on fan reuse:

– Motor housing for unusual resistance when manually rotated

– Blades for warping, balance issues, or damage

– Mounting bracket for corrosion or structural compromise

– Wire connections for signs of overheating or degradation

Warning: Any evidence of electrical damage requires professional assessment before reuse—don’t risk fire hazards by reinstalling compromised components.

Reinstallation Preparation

If reusing the fan, clean mounting surfaces thoroughly and verify the electrical box is rated for ceiling fan installation. Apply a small amount of silicone lubricant to moving parts of the mounting mechanism to prevent future sticking. Organize all components before beginning reassembly to avoid missing parts during installation.

Pro Tip: Take measurements of your existing installation before disassembling completely—this ensures compatibility if replacement becomes necessary.

Final Note: Successfully removing a ceiling fan without screws requires understanding your specific mounting mechanism and applying proper technique rather than brute force. By identifying whether your fan uses spring clips or twist-lock systems, following strict electrical safety protocols, and using the targeted release methods outlined here, you’ll complete this project efficiently without damaging your fixture or ceiling. Remember that patience proves more valuable than power when working with these concealed mounting systems—most removal challenges stem from misidentified mechanisms rather than truly stuck components. With the knowledge gained from this guide, you’re now equipped to handle your screwless ceiling fan removal with professional confidence.

Leave a Reply