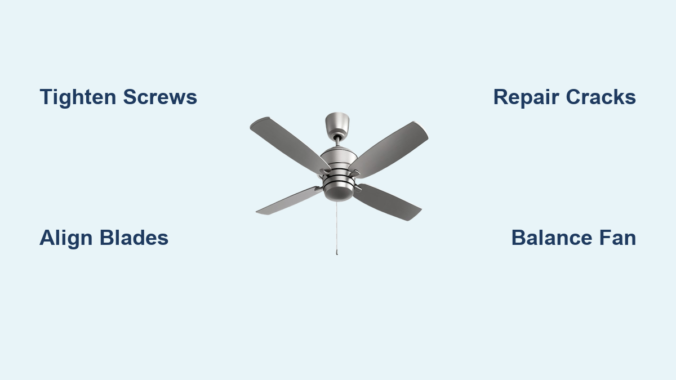

Nothing disrupts a room’s tranquility like the rhythmic thump of a wobbling ceiling fan blade. As these essential home fixtures age, their blades often develop issues that range from annoying vibrations to dangerous cracks and splits. With proper ceiling fan blade repair techniques, you can restore smooth operation and extend your fan’s lifespan by years—saving hundreds compared to full replacement costs. This guide provides actionable solutions for every common blade problem, from minor wobbles to severe damage, so you can tackle repairs confidently with basic tools and minimal experience.

Diagnose the Root Cause of Your Wobbling Fan

Before grabbing your tools, pinpointing your ceiling fan blade repair needs saves wasted effort and ensures lasting results. Most blade problems fall into three distinct categories requiring different approaches.

Wobbling and Vibration Issues

A fan that shakes the entire room typically suffers from uneven blade alignment. This happens when blades rotate out of plane with each other, creating dangerous imbalances. Check blade levelness by placing a yardstick against the ceiling and rotating the fan slowly by hand—the outer tips of all blades should touch the ruler at the same point. If one blade sits higher or lower than others, that’s your primary issue. Common culprits include loose mounting screws (the #1 cause), accumulated dust on one side of blades, or minor warping from humidity exposure.

Visible Damage Assessment

Cracks along blade edges or splits near mounting points create immediate aerodynamic problems that worsen wobbling. Run your palm along each blade’s surface to detect hairline fractures invisible to the eye—these develop from thermal expansion in wood blades or UV degradation in plastic models. Pay special attention to blade tips where stress concentrates during operation. Warning: Blades with cracks longer than 2 inches or splits extending toward the mounting hub require immediate replacement rather than repair for safety reasons.

Loose and Worn Hardware

Vibration gradually works screws loose over time, especially in older fans. Check each blade’s mounting hardware by gently wiggling the blade while the fan is off—any movement beyond slight flex indicates loose connections. Inspect plastic mounting brackets for stress fractures around screw holes, which commonly occur in fans over five years old. Aluminum or steel brackets rarely crack but often develop stripped screw holes that prevent proper tightening.

Essential Tools for Successful Ceiling Fan Blade Repair

Gather these specific items before starting your repair to avoid frustrating ladder climbs mid-project. Most homeowners already have 80% of these basic tools.

- Precision screwdriver set with #1 and #2 Phillips heads (most fan screws require these sizes)

- 12-inch torpedo level (critical for accurate blade alignment)

- Ceiling fan balancing kit (includes adhesive weights and testing clips)

- Wood glue (for wooden blades) or plastic epoxy (for polymer blades)

- Small C-clamps with protective pads (to hold repairs without marring surfaces)

- Non-contact voltage tester (safety essential before any work)

Pro Tip: Place a towel on your ladder step to catch dropped screws—nothing ruins momentum like retrieving a tiny screw from carpet.

Quick Fixes for Minor Blade Problems (Under 30 Minutes)

Most wobbling fans respond to these simple ceiling fan blade repair techniques that require no special skills.

Tighten Loose Blade Screws Properly

Loose screws cause 70% of wobble issues. Turn off power at the breaker, then tighten each blade screw in a star pattern (opposite blades sequentially). Critical mistake to avoid: Over-tightening plastic screws until they strip—stop when resistance increases noticeably. After tightening all screws, test for wobble by rotating blades by hand. If wobbling persists, proceed to blade alignment.

Realign Misaligned Blades in 4 Steps

- Loosen each blade’s mounting screws by 1/4 turn

- Place torpedo level across blade width near the tip

- Adjust blade position until level reads true

- Retighten screws while holding blade perfectly level

Repeat for all blades, checking alignment against each other. This process takes 15-20 minutes but eliminates most persistent wobble issues when done methodically.

Deep Clean Blades to Restore Balance

Dust accumulation weighing down one side of blades creates subtle imbalances. Mix equal parts water and white vinegar in a spray bottle, then wipe both sides of each blade with microfiber cloth. Key insight: Focus on the top blade surfaces—this hidden dust layer significantly affects weight distribution. Allow blades to dry completely before testing fan operation.

Repairing Cracked or Damaged Blades

When visual damage appears, these specialized ceiling fan blade repair techniques restore structural integrity.

Wood Blade Crack Repair That Lasts

For hairline cracks in wooden blades:

1. Widen crack slightly with utility knife

2. Inject slow-set wood glue using syringe

3. Clamp with protective wood blocks for 24 hours

4. Sand smooth and refinish with matching stain

Expert Note: For cracks over 3 inches, reinforce with thin fiberglass tape along the crack underside before gluing—this prevents recurrence from normal flexing during operation.

Plastic Blade Repair That Won’t Fail

Polymer blades require different adhesives:

1. Clean area with isopropyl alcohol

2. Roughen surfaces with 120-grit sandpaper

3. Apply plastic-specific epoxy like J-B Weld PlasticWeld

4. Clamp with rubber-band tension for 6 hours

Avoid superglue on plastic blades—it creates brittle bonds that fail under vibration. For missing chunks, build up with multiple thin epoxy layers, shaping between applications.

Balance Correction Techniques for Smooth Operation

Even undamaged blades develop minor imbalances that cause vibration. These proven methods restore perfect rotation.

The Tape Weight Method (5 Minutes)

- Attach small piece of masking tape to bottom center of one blade

- Run fan at medium speed and note wobble reduction

- Add small weights (coins, washers) to tape until wobble stops

- Replace with permanent adhesive weights from balance kit

Time-Saving Shortcut: Start with the heaviest blade (usually opposite the wobble direction)—this targets the problem area immediately.

Comprehensive Balancing Process

When simple weighting fails:

1. Mark each blade 1-5 with tape

2. Test with weight on Blade 1, then 2, etc.

3. Identify which blade position improves balance most

4. Apply permanent weight at optimal location

This systematic approach solves stubborn wobble issues that random weighting can’t fix, typically taking 15-20 minutes.

When Replacement Beats Repair

Some damage exceeds practical repair—knowing when to replace saves wasted effort.

Replacement Indicators You Can’t Ignore

Replace blades immediately if you see:

– Cracks extending more than 1/3 the blade length

– Warping visible when laying blade on flat surface

– Water damage causing delamination in wood blades

– Multiple previous repairs on same blade

Cost Reality Check: Replacement blades cost $15-$30 each, while professional repair often exceeds $100—making DIY replacement more economical than complex fixes.

Finding Perfect Replacement Blades

- Measure blade length from tip to mounting hole center

- Note hole pattern (most use 2-hole or 4-hole configurations)

- Check fan model number on motor housing

- Search “your model + replacement blades” online

Universal blades work for many fans but verify compatibility—mismatched weights create new balance problems.

Preventive Maintenance That Prevents Future Repairs

Avoid recurring ceiling fan blade repair needs with these simple habits.

Monthly Cleaning Routine

Wipe both blade sides with damp microfiber cloth while fan is off. Critical step: Clean the top surfaces where dust accumulates invisibly—this hidden layer significantly affects balance over time. For high ceilings, use an extendable duster monthly and deep clean quarterly.

Seasonal Inspection Checklist

Before summer and winter seasons:

– Check all screws for tightness

– Inspect blades for new cracks or warping

– Verify smooth operation at all speeds

– Listen for unusual clicking or grinding

Catching small issues early prevents 90% of major blade problems.

Safety Protocols for Risk-Free Repairs

Never compromise on these critical safety measures during ceiling fan blade repair.

Electrical Safety Non-Negotiables

Always turn off power at the circuit breaker—not just the wall switch—and verify with non-contact voltage tester at the fan canopy. Fatal mistake to avoid: Assuming the wall switch cuts all power—many fans have separate lighting circuits. Keep the breaker off and labeled until repairs finish.

Ladder Safety Essentials

Use an A-frame ladder on solid flooring—not step stools—and maintain three points of contact while working. Have a helper stabilize the ladder base, especially with ceiling heights over 9 feet. Pro Tip: Place a non-slip mat under ladder legs on hardwood or tile floors—this prevents dangerous slips during adjustment.

Regular maintenance prevents most ceiling fan blade repair scenarios, but when issues arise, these targeted solutions restore smooth operation quickly. Remember that minor wobbles typically resolve with screw tightening and balancing, while visible damage requires material-specific repairs. When replacement becomes necessary, matching blades properly ensures lasting results. By incorporating seasonal inspections and monthly cleaning into your routine, you’ll minimize future repair needs and enjoy quiet, efficient cooling for years. The most successful ceiling fan blade repair is the one you never need to perform—through consistent preventive care that keeps your fan operating at peak performance.

Leave a Reply