You’ve admired that elegant cathedral ceiling and decided to install a ceiling fan—but hit a roadblock. Unlike flat ceilings, vaulted spaces require special mounting solutions because standard electrical boxes can’t handle the weight and angle. Installing a fan directly into drywall or flimsy framing risks catastrophic failure, potentially causing severe injury or property damage. This isn’t just about tools and lumber; it’s about understanding why cathedral ceiling fan boxes demand precise engineering. You’ll learn critical safety protocols, structural requirements, and why skipping professional verification could void your insurance. Most importantly, we’ll clarify when DIY is dangerously inappropriate versus when a custom box becomes a viable solution.

Why Cathedral Ceilings Demand Special Fan Mounting Solutions

Standard ceiling fan boxes fail catastrophically on vaulted ceilings because they’re designed for vertical downward force, not the dynamic lateral stresses created by angled installations. When a fan operates on a 30-45° slope, centrifugal force generates sideways torque that can rip flimsy mounts from drywall in weeks. The National Electrical Code (NEC) Article 422.18 explicitly prohibits mounting fans to standard plastic or shallow metal boxes in these scenarios—they simply lack the 50+ pound structural rating required for moving fixtures. You’ll recognize improper mounting by subtle warning signs: a faint clicking during operation, visible drywall cracks around the canopy, or the fan wobbling even after balancing. These aren’t minor nuisances; they indicate imminent structural failure where a 15-30 pound fan could plummet unexpectedly.

Critical Structural Requirements You Must Verify

Before cutting a single piece of wood, confirm these non-negotiable elements:

– Joist identification: Locate ceiling joists using a stud finder with deep-scan capability (minimum 2″ depth detection). Mark both edges of every joist with painter’s tape—never rely on single-point detection.

– Load capacity: Joists must support at least 75 pounds static load (NEC 314.27(C)). Test by drilling a 1/8″ pilot hole at the mounting point; if the drill slips through with minimal resistance, the wood is compromised.

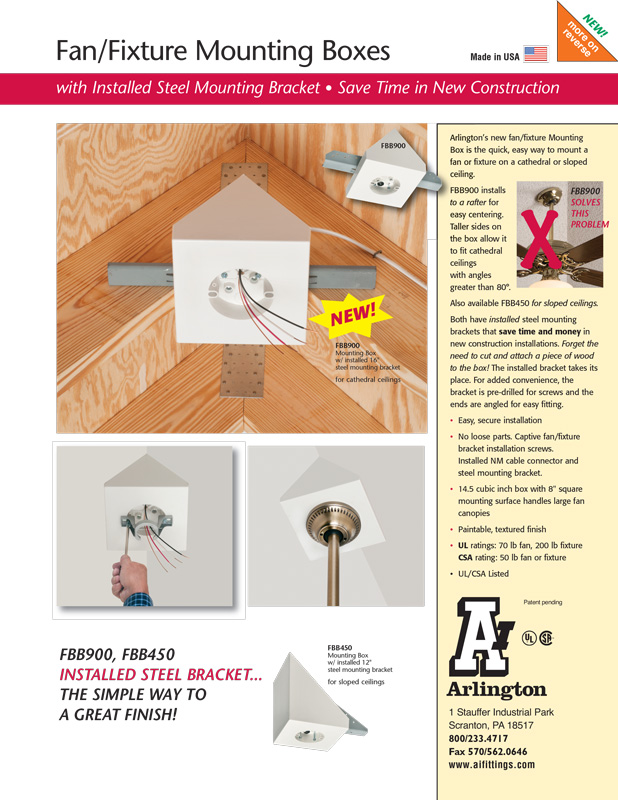

– Electrical box rating: Only use UL-listed “fan-rated” boxes explicitly marked for angled installations (e.g., “Suitable for Ceiling Fans on Sloped Ceilings”). Standard octagon boxes lack the reinforced mounting brackets needed.

Common DIY Fatal Errors to Avoid

Mistake #1: Using drywall anchors instead of direct joist mounting

Consequence: Even heavy-duty toggle bolts fail under rotational stress—fans have torn anchors from ceilings within 3 months.

Mistake #2: Building boxes from particleboard or MDF

Consequence: Humidity fluctuations cause swelling/warping, cracking drywall and loosening screws.

Mistake #3: Ignoring wire fill capacity

Consequence: Overcrowding wires in undersized boxes creates fire hazards; NEC 314.16(B) requires 2.25 cubic inches per #14 wire.

Step-by-Step Construction of a Code-Compliant Fan Box

Constructing a cathedral fan box requires precise geometry to transfer weight vertically to structural supports. This process takes 3-4 hours for experienced DIYers but demands absolute accuracy—errors of 1/8″ can cause misalignment that stresses motor housings.

Selecting Safe Materials and Tools

Required materials (verified for structural integrity):

– Pressure-treated 2×6 lumber (for exterior moisture resistance)

– 3/4″ exterior-grade plywood (void-free Baltic birch preferred)

– 3″ corrosion-resistant structural screws (not nails)

– 2-gang metal fan-rated electrical box with adjustable mounting plate

– 10-12 gauge copper grounding wire (8″ length)

Essential tools:

– Digital angle finder (accuracy ±0.5°)

– Framing square with degree markings

– Oscillating multi-tool (for precise drywall cuts)

– Torque screwdriver (calibrated to 25 in-lbs)

Building the Angled Support Frame

- Calculate the mounting angle: Measure your ceiling slope with a digital angle finder. For a typical 30° cathedral ceiling, set your miter saw to 30° for cross-cuts.

- Cut primary supports: Cut two 2×6 blocks to 12″ length at your measured angle. These become the vertical load bearers.

- Create the base plate: Cut a plywood rectangle 8″ wider than your electrical box. Drill a 2.5″ hole centered for box insertion.

- Assemble the cradle: Position blocks perpendicular to the base plate at calculated spacing (typically 6″ apart for 30° ceilings). Secure with three 3″ screws per block, pre-drilled to prevent splitting.

Pro Tip: Test fit the assembly before wiring. Place it against the ceiling joist—there should be zero gaps between the base plate and joist. Shim with cedar shingles if needed; never force alignment.

Integrating Electrical Components Safely

Critical sequence:

1. Mount the metal electrical box to the plywood base before attaching to joists using #10-32 machine screws through pre-drilled holes.

2. Run all wiring through the joist via a 1.25″ hole drilled 2″ from the top edge (per NEC 200.6). Never staple wires to box sides.

3. Secure cable clamps outside the box—NEC 314.17(A) requires 1/4″ minimum clearance between clamp and box edge.

4. Torque all connections to manufacturer specs (usually 14 in-lbs for wire nuts).

Visual checkpoint: When installed, the box’s mounting plate must sit perfectly flush against drywall after cutting the access hole. Any tilt >2° indicates frame misalignment—disassemble and rebuild.

When to Absolutely Call a Professional

Certain scenarios make DIY fan boxes illegal and lethally dangerous:

– Open-web trusses: Cutting or modifying these engineered systems requires engineer approval—DIY voids structural warranties.

– Ceiling slopes >45°: Angles steeper than a standard roof pitch (12/12) demand custom steel bracing beyond wood-framing capabilities.

– Existing electrical modifications: If previous owners added junction boxes in the attic space, you risk violating NEC 300.15 requirements for accessible wiring.

A licensed electrician charges $150-$300 for certified installation but provides critical safeguards: stamped engineering diagrams, insurance-covered workmanship, and compliance verification. One homeowner’s attempt to save money resulted in a fan detachment that destroyed a $4,000 antique table—repairs cost 10x professional installation.

Long-Term Safety Maintenance Protocol

Your fan box requires active monitoring to prevent hidden failures:

– Monthly: Operate fan on high speed while standing on a ladder (never chairs!). Place palm against canopy—if you feel vibration beyond mild humming, shut off immediately.

– Biannually: Remove fan blades and inspect for screw hole elongation. Replace any stripped holes with epoxy-filled hardwood dowels.

– After storms: Check for new drywall cracks within 12″ of the mount. These indicate structural shifting requiring professional assessment.

Urgent red flags:

⚠️ Rust-colored dust around mounting screws (indicates metal fatigue)

⚠️ Persistent humming after capacitor replacement (sign of frame resonance)

⚠️ Temperature above 100°F at canopy (use IR thermometer)—indicates electrical overload

Final Note: Building a cathedral ceiling fan box isn’t a standard DIY project—it’s structural engineering with life-safety implications. While this guide outlines critical requirements, always consult your local building department for slope-specific codes (many jurisdictions ban DIY boxes over 35° slopes). For most homeowners, purchasing a pre-engineered solution like the Arlington Industries RMCB-15 or collaborating with an electrician is the only responsible path. Remember: that elegant fan becomes a lethal hazard when improperly mounted. Prioritize certified safety over cost savings—your family’s wellbeing depends on it. If in doubt, stop work immediately and contact a licensed professional.

Leave a Reply