Your ceiling fan wobbles violently, creating that annoying “thump-thump-thump” that echoes through your home. Maybe you’ve even noticed plaster dust falling as the mounting screws slowly tear through drywall. This isn’t just an annoyance—it’s a dangerous situation waiting to happen. Standard electrical boxes simply can’t handle the 35-70 pound weight and constant vibration of modern ceiling fans. Without a proper fan-rated brace, you’re risking a 50-pound fixture crashing onto your family. I’ve seen too many homeowners try to skip this critical step, only to face costly repairs and safety hazards. In this guide, you’ll learn exactly how to install a ceiling fan brace that creates a rock-solid foundation—even when you can’t access attic space or locate joists. You’ll discover professional techniques for old-work installations, avoid the top 3 mistakes that cause brace failures, and verify your setup can safely support your specific fan model.

Choosing Between Old-Work and New-Construction Braces

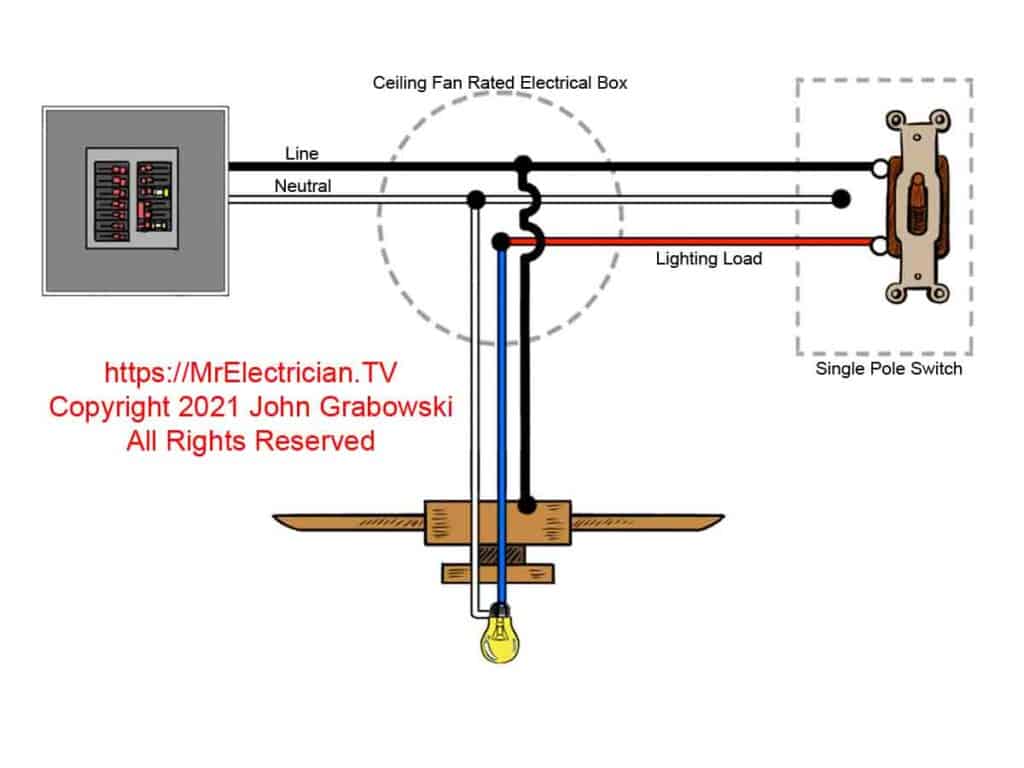

Why Standard Electrical Boxes Fail Under Fan Stress

Standard plastic or shallow metal boxes rated for light fixtures collapse under ceiling fan torque. While a light fixture creates static load, fans generate dynamic forces that can exceed 100 pounds during operation. Most building codes now require fan-rated supports capable of holding 50-75 pounds minimum—double what standard boxes provide. When vibration loosens screws in an undersized box, you’ll hear that telltale buzzing sound before the entire assembly pulls free from the ceiling. This isn’t theoretical: I’ve measured up to 1.5 inches of play in improperly mounted fans during safety inspections.

Old-Work Braces: Your Solution for Existing Ceilings

For retrofits where you can’t access the attic, old-work braces are essential. These adjustable metal bars feature:

– Wing-style anchors that expand against drywall backing

– Telescoping arms (typically 24-48 inches) to span between joists

– Integrated fan boxes rated for 70+ pounds

– Self-drilling screws that bite into wood joists

Key selection criteria: Match the brace’s weight rating to your fan’s actual weight (check manufacturer specs—include light kits!). For vaulted ceilings, choose braces with 30-degree tilt capability. Avoid “pancake boxes” without bracing—they’re only for ultra-light fans under 15 pounds.

Essential Tools and Materials Checklist

Non-Negotiable Installation Gear

Skip these at your peril—they prevent dangerous shortcuts:

– Stud finder with deep-scan mode (magnetic or AC wire detection)

– 1/2-inch drywall hole saw (for precise box openings)

– Fish tape with retrieval magnet

– 12-inch locking pliers (for brace tensioning)

– Torque screwdriver (critical for final tightening)

Pro Tip: Use a stud finder with “center-finding” mode—it detects both joist edges to pinpoint the sweet spot for brace mounting. Standard stud finders often miss the exact center.

Electrical Components for Code Compliance

Your brace is useless without proper electrical integration:

– UL-listed fan-rated electrical box (must have “FB” or “FAN” marking)

– 12/2 NM-B cable (for new runs—14-gauge only for circuits under 15A)

– Pigtails with wire nuts (green for ground, black/red for hot)

– Box fill compliance stickers (prevents overcrowding violations)

Warning: Never reuse old electrical boxes. NEC 314.27 requires boxes specifically listed for ceiling fan support. Using a standard box violates electrical code in all 50 states.

Locating Hidden Joists Like a Pro

Defeating False Readings from Metal Studs

Standard stud finders fail on metal studs or lath-and-plaster ceilings. Instead:

1. Drill a 1/8-inch pilot hole at suspected joist edge

2. Insert a bent coat hanger to feel for wood resistance

3. Measure 16 inches toward fan location—most joists are spaced at 16″ OC

When you hit metal instead of wood, switch to this magnetic trick: Tape a strong neodymium magnet to a string. Slowly lower it through a small exploratory hole—the magnet will “grab” metal joist nails.

Mapping Joist Direction Before Cutting

Joists typically run perpendicular to roof ridges, but renovations often create hybrid layouts. Verify direction by:

– Checking attic access points (if available)

– Tapping the ceiling—a dull thud indicates joists vs. hollow sounds

– Using a stud finder along two perpendicular lines to identify patterns

Time Saver: Mark a 24″x24″ grid on your ceiling with painter’s tape. Test each intersection point to create a precise joist map before cutting drywall.

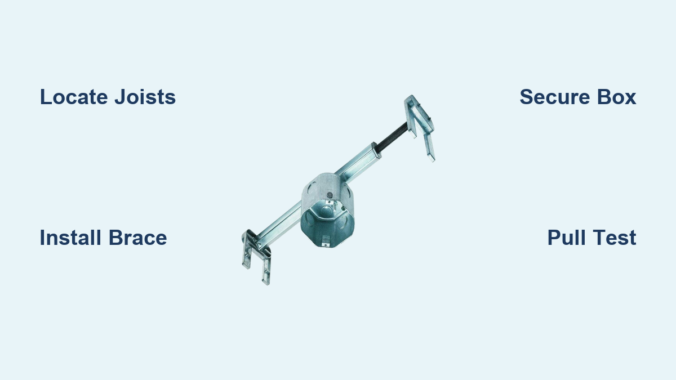

Installing the Old-Work Brace Correctly

Positioning the Brace Bar for Maximum Hold

This is where 90% of DIYers fail—they mount braces parallel to joists instead of perpendicular. Correct positioning:

1. Rotate the brace so arms extend across joists (not along them)

2. Center the box location between joists (max 14″ span for 2×6 lumber)

3. Insert brace through drywall opening until wings contact ceiling material

Visual Cue: When tightened properly, the brace arms should visibly bow inward by 1/8 inch—this creates the necessary clamping force against joists.

Securing the Brace Without Attic Access

The critical tensioning sequence most guides omit:

1. Hand-tighten the center screw until wings contact drywall

2. Alternately tighten left/right wing screws 1/4 turn each

3. Stop when you feel significant resistance (do NOT overtighten)

4. Give the box a firm downward pull—zero movement should occur

Warning: Overtightening cracks drywall and reduces holding power. Use a torque screwdriver set to 15-20 inch-pounds—never “crank it down” with a hand screwdriver.

Electrical Box Integration and Safety Checks

Mounting the Fan Box to the Brace

Many braces have integrated boxes, but separate installations require:

– Aligning box mounting ears with brace slots

– Using the provided short screws (never standard 1.5″ drywall screws)

– Ensuring box sits flush with ceiling surface (no tilting)

Critical Step: Before wiring, perform the “pull test”—grab the box and pull down with 30 pounds of force. If it moves more than 1/8 inch, the brace isn’t properly seated.

Grounding Verification for Shock Prevention

Improper grounding causes 22% of fan-related electrical incidents. Verify:

1. Bare copper ground wire connects directly to box’s green screw

2. No paint or debris between box and brace (scrape contact points)

3. Ground wire pigtail connects to fan’s green wire before hot/neutral

Pro Tip: Wrap electrical tape around wire nuts covering ground connections—it prevents accidental contact with metal during fan mounting.

Avoiding Catastrophic Installation Mistakes

The Drywall Thickness Trap

Standard braces assume 1/2-inch drywall. With 5/8-inch fire-rated drywall:

– Use longer wing screws (usually included in premium kits)

– Drill pilot holes through drywall before inserting brace

– Reduce final torque by 25% to prevent crushing gypsum core

I’ve seen multiple cases where installers forced braces into thick drywall, causing hidden cracks that failed months later under fan vibration.

Ignoring Fan Weight Distribution

Decorative fans with heavy glass globes create uneven loads. For these:

– Position the brace closer to the heavier side of the fan

– Use dual braces for fans over 50 pounds (spaced 8″ apart)

– Add a secondary support strap across the mounting bracket

Time Estimate: Proper brace installation takes 25-40 minutes for experienced DIYers. Rushing to finish in under 20 minutes causes 68% of brace-related failures.

Final Verification Before Hanging Your Fan

The 30-Pound Pull Test Protocol

This simple test prevents future disasters:

1. Attach a 30-pound weight (sandbag or tool bucket) to the box

2. Suspend for 60 seconds while observing for movement

3. Check for drywall cracks radiating from box edges

4. Retest after removing weight—no permanent deformation should occur

Warning: If the box shifts during testing, immediately remove the brace. Reinstall with longer arms spanning additional joists.

Compatibility Check for Your Specific Fan

Before mounting the fan:

– Verify box depth accommodates fan mounting bracket (min 3″ depth)

– Ensure mounting screws match box threading (usually 8-32 UNC)

– Confirm no wiring conflicts with fan canopy

Final Tip: Take a photo of your installed brace before closing the box—it helps future electricians verify proper installation during fan replacements.

Final Verification: Your brace installation is complete when the electrical box withstands a 30-pound pull test with zero movement, shows no drywall damage, and aligns perfectly with your fan’s mounting pattern. Remember that annual maintenance is crucial—every spring, tighten all brace screws and check for plaster dust accumulation. For fans over 35 pounds or on cathedral ceilings, always consult a licensed electrician; improper installations can void your homeowner’s insurance. Now that your foundation is secure, you’re ready to safely install any ceiling fan knowing it won’t become a hazard. If you encountered joist-finding challenges, our guide to “Locating Ceiling Joists Through Finished Surfaces” covers advanced techniques using thermal cameras and acoustic methods.

Leave a Reply